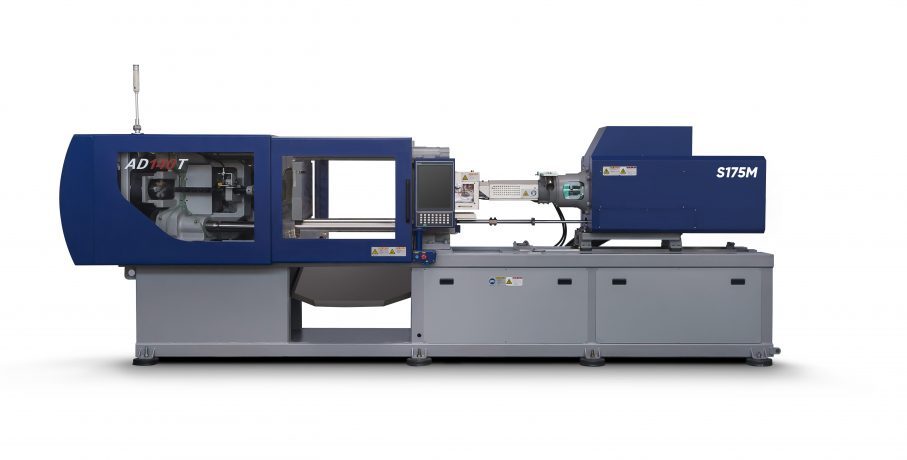

High Precision Plastic Injection Molding Machines

LOG Injection Molding Machine manufactures a wide range of high-precision, plastics injection molding machine for diverse plastic molding applications. LOG is dedicated to improving your overall plastic injection molding productivity and profitability. We work with you to ensure we are providing the best plastic molding solutions based on your application and business requirements. You can count on us for advanced technology, application expertise, and after-sales support.

LOG has two main plastics injection molding machine platforms:

S8 Series Hydraulic Servo high energy efficient and precision plastics injection molding machine

S9 Series High-end Servo precision plastics injection molding machine

Solutions based on your application and business requirements

LOG works with you to ensure that we are providing the best molding solutions based on your application and business requirements. You can count on us for the advanced technology and applications expertise to help improve your overall plastics injection molding productivity and profitability. LOG’s S8 and S9 Series Servo injection molding machines offer the superior clamping force of hydraulic machines and the precision, repeatability, energy savings, and reduced noise of electric machines.

In addition to our wide range of new plastics injection molding machinery, we have an extensive after sales support team. From parts to training to service, our responsive and knowledgeable technicians are here to help with any of your needs.

Worldwide plastics injection molding machine capabilities

LOG is a worldwide company dedicated to helping plastic processors compete more effectively in a global market. Whether your plastics molding operation is local, or half way around the world, we have the equipment, engineering expertise, and support to meet your injection molding machinery requirements.

Why buy used when you can buy new.

We are here to help with all your plastics processing needs. Virtus Equipment will cover your entire spectrum of size-reduction and recycling machinery needs.