Purchasing an injection molding machine is a major capital investment that directly impacts production efficiency, product quality, and long-term operating costs. Whether you are buying your first automatic plastic molding machine or upgrading an existing line, avoiding common mistakes can save time, money, and production downtime.

As a trusted LOG Injection Molding Machine supplier in the USA, we’ve worked with manufacturers across industries—automotive, medical, and packaging, consumer goods, and electronics. Below are the 10 most critical mistakes to avoid when you buy an injection molding machine, along with expert guidance to help you make the right decision.

Many buyers focus only on machine size or price when purchasing an injection molding machine. However, long-term success depends on build quality, service support, mold compatibility, energy efficiency, and production stability. Avoiding these mistakes ensures higher ROI, consistent output, and lower life-cycle costs.

1. Ignoring Quality Issues:

One of the biggest mistakes is assuming all injection molding machines offer similar quality.

What to check:

- Frame rigidity and machine structure

- Repeatability and shot-to-shot accuracy

- Hydraulic or servo system stability

- Proven performance in real production environments

Low-quality machines often result in inconsistent parts, higher scrap rates, and frequent breakdowns.

2. Overlooking After-Sales Service Issues:

Many buyers realize too late that service support matters as much as machine specifications.

Avoid suppliers who lack:

- Local USA-based service engineers

- Spare parts availability

- Clear warranty terms

- Technical support for troubleshooting

A reliable injection molding machine supplier should provide long-term service, not just a machine sale.

3. Choosing the Wrong Scope of Application:

Not all machines suit every product or industry.

Before purchasing an injection molding machine, evaluate:

- Product size and wall thickness

- Plastic materials used (PP, ABS, PET, PVC, engineering resins)

- Cycle time requirements

- Multi-cavity or single-cavity production

Choosing a machine outside your actual production needs leads to inefficiency and higher operating costs.

4. Configuration Issues:

A common mistake is buying an under-configured or over-configured machine.

Key configuration elements include:

- Injection unit size

- Clamping force

- Screw diameter and L/D ratio

- Servo-hydraulic vs hydraulic system

Correct configuration ensures optimal performance across the entire injection molding machine production process.

5. Deep Matching of Mold Compatibility:

Mold compatibility is often underestimated.

You must ensure:

- Proper platen size and tie-bar spacing

- Adequate injection pressure and volume

- Compatibility with hot runner systems

- Mold mounting and ejection alignment

A mismatch between mold and machine leads to poor part quality and frequent mold damage.

6. Personnel Training System Construction:

Even the most advanced automatic plastic molding machine fails without trained operators.

Buyers often forget to plan for:

- Machine operation training

- Preventive maintenance education

- Basic troubleshooting skills

A professional injection molding machine manufacturer should provide training programs to support efficient operation.

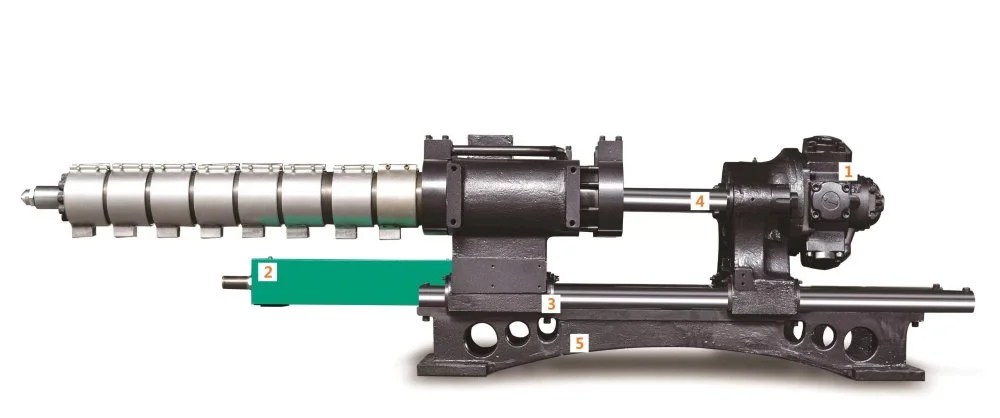

7. Deep Inspection of Core Components:

Core components define machine lifespan.

Always evaluate:

- Servo motors and hydraulic pumps

- Control systems and PLC reliability

- Heating bands and temperature control accuracy

- Electrical components and wiring standards

High-quality components ensure long-term reliability and stable production output.

8. Professional Evaluation of Accessory Status:

Small accessories significantly affect production stability.

Don’t ignore:

- Lubrication systems

- Cooling line design

- Safety interlocks

- Sensors and monitoring systems

Details often determine whether your machine runs smoothly or faces frequent downtime.

9. Appearance and Structure Inspection:

While appearance alone doesn’t define performance, it reflects manufacturing standards.

Check for:

- Clean welds and solid base construction

- Proper cable routing

- Noise and vibration during operation

Structural quality impacts machine precision and service life.

10. Focusing Only on Injection Molding Machine Price:

The biggest mistake is buying solely based on price.

A low injection molding machine price may hide:

- Higher energy consumption

- Expensive maintenance

- Shorter machine lifespan

- Limited service support

Instead, evaluate total cost of ownership, including energy use, uptime, service, and resale value.

Conclusion:

Buying an injection molding machine is not just a purchase – it’s a long-term manufacturing decision. Avoiding these ten mistakes helps ensure consistent quality, optimized production, and sustainable profitability.

With decades of experience, LOG Injection Molding Machine delivers hydraulic and servo-hydraulic injection molding machines engineered for reliability, energy efficiency, and maximum output—backed by professional support across the USA.

Frequently Asked Questions:

1. What should I consider before purchasing an injection molding machine?

Focus on product requirements, mold compatibility, machine configuration, service support, and long-term operating costs—not just price.

2. Is a servo-hydraulic injection molding machine better than a hydraulic one?

Servo-hydraulic machines offer higher energy efficiency, better precision, and lower operating costs, making them ideal for high-volume production.

3. How do I choose the right injection molding machine supplier?

Look for proven experience, strong technical support, spare parts availability, training programs, and USA-based service.

4. What affects injection molding machine price the most?

Clamping force, injection unit size, automation level, servo systems, brand reputation, and service coverage all influence price.

5. Can one injection molding machine handle multiple products?

Yes, if properly configured and matched with compatible molds, a machine can support multiple applications efficiently.