In today’s fast-paced manufacturing world, every second saved and every watt conserved counts. When you choose plastic injection molding equipment, your choice of machine can make or break your competitiveness. That’s why more manufacturers turn to servo-driven plastic injection molding machines – and why, as a trusted Injection Molding Machine Supplier in USA, LOG Injection Molding Machine strongly recommends servo-driven systems for modern production. This blog explores the clear advantages of servo-driven plastic injection molding machines and how they can transform your production line.

What Is a Servo-Driven Injection Molding Machine?

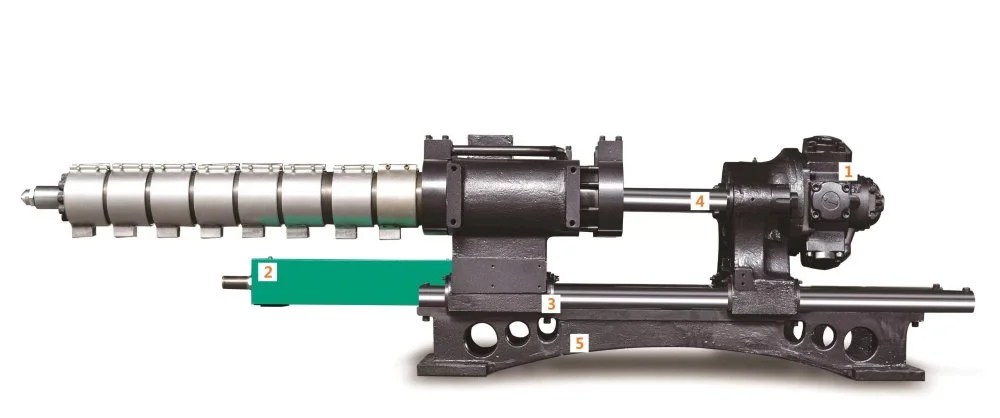

A servo-driven plastic injection molding machine replaces or augments traditional hydraulic drives with servo motors that control injection, clamping, screw rotation and ejection motions. Unlike conventional hydraulic machines – where pumps run continuously – servo motors draw power only when needed, responding precisely to demands for motion, pressure, and speed.

This intelligent, demand-based operation is what sets servo-driven machines apart – and gives manufacturers the leverage to deliver higher quality and sustainable production.

Key Advantages of Servo-Driven Injection Molding Machines

- Substantial Energy Savings & Better Sustainability

One of the most compelling benefits of servo-driven machines is energy efficiency. Because servo motors only run when motion is required, overall energy consumption can drop dramatically – in many cases 30% to 80% less than conventional hydraulic machines.

This can lead to major reductions in electricity bills over time, and helps manufacturers meet sustainability and environmental goals. Reduced power consumption also means less heat generation and diminished cooling load for the factory – contributing further to energy savings.

- Higher Precision, Consistency & Part Quality

Servo-driven systems give you highly accurate and repeatable control over injection speed, pressure, screw position, clamping force, and ejection timing. This fine-tuned control ensures each cycle performs consistently – resulting in uniform, high-quality parts with tight dimensional tolerances.

Consistency is critical especially in sectors like electronics, medical devices, and automotive components – where even small deviations can lead to defects or failed parts. Servo-driven injection machines reduce risks of common molding issues such as flash, warpage, short shots, or incomplete fills.

- Shorter Cycle Times & Higher Productivity

Because servo motors offer rapid response, acceleration, and deceleration, operations like mold closing/opening, injection, and ejection can be performed faster and more smoothly. This reduces cycle time per piece and increases throughput – enabling higher-volume production without compromising quality.

Faster cycles mean you can meet tight delivery timelines, scale up output, and improve overall manufacturing efficiency.

- Lower Maintenance & Operating Costs over Time

Servo-driven injection molding machines generally have fewer moving parts compared to traditional hydraulic machines, leading to less wear and tear. That means lower maintenance frequency reduced downtime, and longer machine life.

Additionally, because servo systems operate more cleanly – generating less heat and noise – operating environment improves, and you can save on cooling and maintenance of auxiliary systems.

- Improved Flexibility & Versatility for Diverse Applications

Servo-driven machines are adaptable: the precise control over speed, pressure and timing makes them suitable for a wide variety of plastics, mold types, and product complexities – from simple consumer goods to high-precision medical or electronic parts.

Whether you’re shifting between different molds or switching production runs frequently, a servo-driven injection molding machine provides the flexibility needed to adapt quickly and maintain consistent quality.

- Quieter, Cleaner, and Safer Operation

Servo-driven systems generally produce less noise and vibration compared to traditional hydraulic machines. That makes the production environment more comfortable and safer for operators.

Fewer leaks, lower hydraulic oil usage, and reduced thermal load contribute to a cleaner, more efficient workspace.

- Long-Term ROI – Efficiency, Quality, and Profitability

Though the initial investment for servo-driven machines may be higher than basic hydraulic models, the cumulative benefits – energy savings, lower maintenance, higher throughput, consistent part quality, reduced waste – contribute to a strong return on investment over time.

For manufacturers aiming to scale production, reduce operating costs, and ensure high-quality output, servo-driven injection molding machines are not just a purchase – they’re a strategic investment.

Why Choose LOG Injection Molding Machine as Your Supplier & Manufacturer

At LOG Injection Molding Machine, we understand the demands of modern manufacturing – from cost pressures and energy constraints to product quality and turnaround time. We design our servo-driven machines with these priorities in mind:

- Advanced servo drive systems for energy efficiency and consistent performance.

- High-precision control over injection, clamping, and ejection for high-quality molding.

- Optimized hydraulic/servo hybrid or fully servo-hydraulic configurations for versatility.

- Robust build quality ensuring durability, low maintenance, and long service life.

- Flexibility to customize machines for various applications: automotive, electronics, consumer goods, medical devices and more.

When you partner with LOG, you’re not just buying a machine – you’re investing in efficiency, quality, and competitive advantage.

Conclusion:

Switching to a servo-driven plastic injection molding machine is more than a technological upgrade – it’s a transformation in how you manufacture. From substantial energy savings, to superior precision, faster throughput, lower maintenance, and cleaner operations – the benefits are both immediate and long-term.

If you want to optimize production, reduce costs, and deliver consistent quality at scale – servo-driven plastic injection molding machines are a smart, future-proof choice.

At LOG Injection Molding Machine, we’re dedicated to helping you harness these advantages. By investing in a high-quality servo-driven machine today, you set your production up for better performance, lower costs, and greater competitiveness tomorrow.

Frequently Asked Questions:

1. What is a servo-driven injection molding machine?

A servo-driven machine uses servo motors to control key functions (injection, clamping, and ejection) with high precision – unlike traditional hydraulic machines that run pumps continuously.

2. How much energy can I save by using a servo-driven machine?

Compared to standard hydraulic presses, servo-driven machines can reduce energy consumption by 30% to 70-80%, depending on usage and production volume.

3. Are servo-driven machines more precise than traditional hydraulic machines?

Yes. Servo control allows precise management of injection speed, clamping force, pressure, and ejection timing – delivering consistent, repeatable results for every cycle.

4. Do servo machines require more maintenance?

No – typically the opposite. With fewer moving parts and less hydraulic stress, maintenance intervals are longer, and wear-and-tear is reduced, leading to lower downtime.

5. Can servo-driven molding machines handle different types of plastics and complex molds?

Yes. The precise control in speed, pressure, and timing allows servo-driven machines to accommodate a wide variety of plastics (general purpose, engineering plastics, etc.) and mold types — from simple to complex, thin-wall to multi-cavity.

6. Are servo-driven machines suitable for small production runs or only large-scale manufacturing?

They are suitable for both. Even for small or medium-sized runs, the benefits of energy savings, flexibility, and part quality can make them a wise choice.

7. Is switching to servo-driven injection molding worth it for small manufacturers?

Even small-to-medium manufacturers can benefit – especially if they value part quality, production flexibility, and lower operating costs. Over time, energy savings and reduced waste can offset the cost of investment.