Coming Soon! The Go-To Portal for Injection Molding Machines & Spare Parts Keep Me Updated

LOG-S8 90

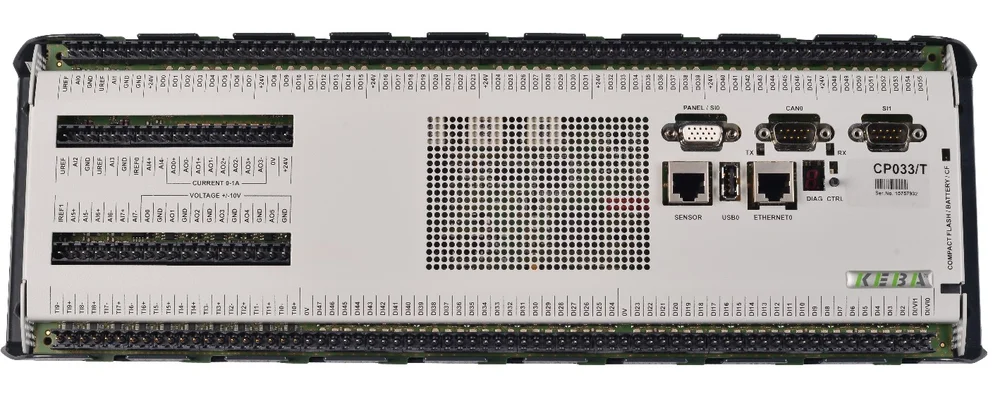

The LOG-S8 90 is an affordable, high-precision, high-speed plastic injection molding machine featuring a unique, rigid third-platen flange design with a highly adjustable L/D ratio and a user-friendly, smart Industry 4.0 KEBA control system that manages all operational aspects.

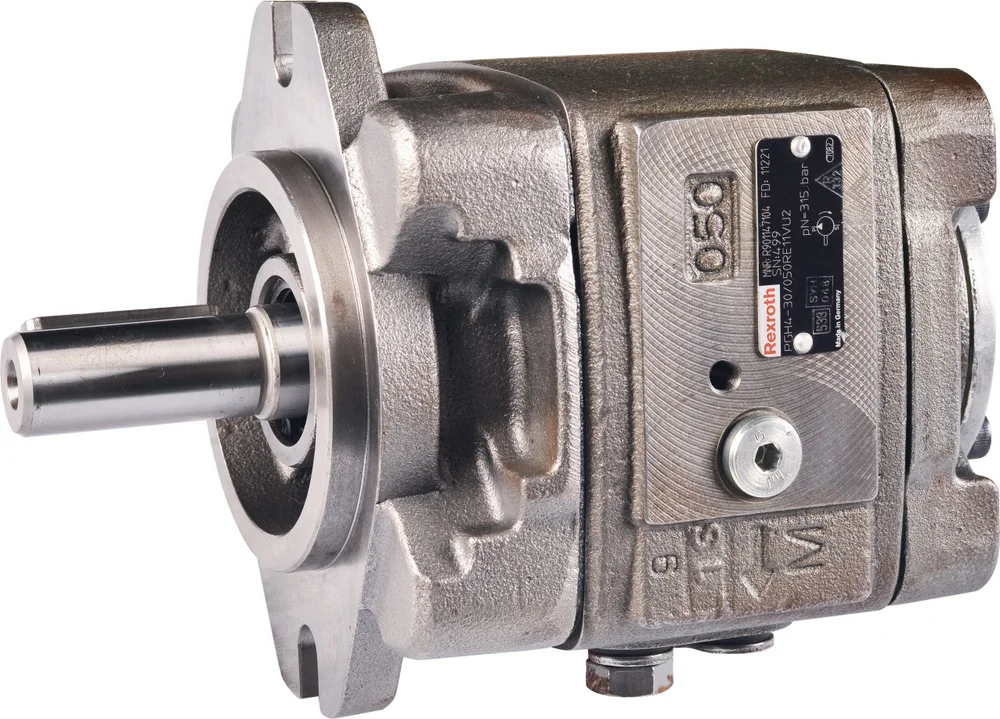

It includes a 5-point dual-toggle mechanism for high force amplification and a robust, high-power servo-hydraulic system that efficiently generates 90 metric tons of clamping force while reducing energy consumption by up to 80%.

Its modular design enables quick and easy mold changes, and the use of well-known international components simplifies maintenance and minimizes downtime.

The LOG-S8 90 is ideally suited for producing high-quality products across various industries, including food packaging, household products and appliances, electronics, automotive, pipe fittings, toys, gifts, and other sectors.

| Shot volume(PS) | Screw diameter | Clamping force | Opening stroke | Tie-Bar Distance | Mold thickness | Pump motor |

|---|---|---|---|---|---|---|

| 144g | 35mm | 900kn | 320mm | 360 x 360(mm) | 150-360(mm) | 14kw |

Effect Test Cases

Test Case

Test condition

Hydraulic pump:

Machine settings: Each machine had the same settings

Processing time: Several hours

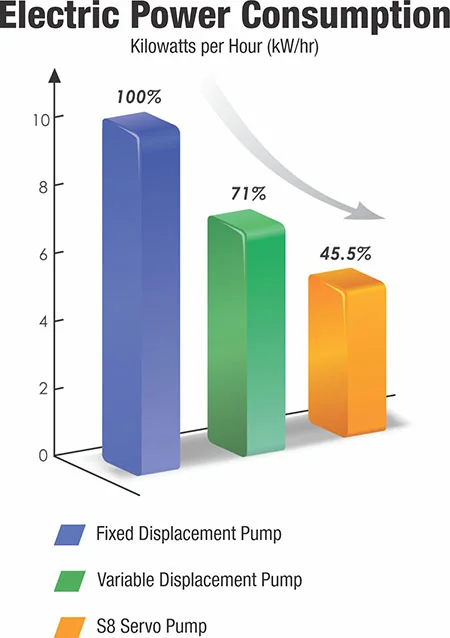

The test results show an energy savings of 45.5% when using the S8 servo system compared to a similar-sized fixed displacement system IMM with up to 80% energy savings.

| Plastic Machine Sampling Analysis | 250T Fixed Displacement MM | 250T Variable Displacement IMM | 250T Servo System IMM |

|---|---|---|---|

| Test Time | 2 | 2 | 2 |

| Oil Temperature | 55 | 45 | 40 |

| Close Mold | 1.8 | 1.8 | 1.6 |

| Open Mold | 1.4 | 1.4 | 1.4 |

| Injection | 1.5 | 1.2 | 1 |

| Hold Pressure | 0.5 | 0.4 | 0.2 |

| Charging | 2.2 | 2.2 | 1.8 |

| Production Cycle | 7.4 | 7 | 6 |

| Total Shot | 973 | 1028 | 1200 |

| Power Consumption per hour (kW/h) | 12.3 | 10.6 | 8.8 |

| Annual Power Consumption (kW) | 66,420 | 57,420 | 47,520 |

Note: The data above is based on running the machine for 18 hours per day, 25 days per month, and 300 days per year.

Note: *The tonnage shown in the model number is in metric tons, equivalent to approximately 1.1 US tons. Please note when selecting a machine for your application.

The LOG S8 90 Ton Injection Molding Machine is a high-performance servo-driven model designed for precision, energy efficiency, and durability. It’s ideal for manufacturing small to medium-sized plastic components across industries such as automotive, packaging, electronics, and household products.

The price of the LOG S8 90 Ton Injection Molding Machine varies depending on specifications, optional features, and customization requirements. For an accurate quotation, contact LOG’s sales team for the latest injection molding machine price list and offers.

Yes, the LOG S8 90 Ton Injection Molding Machine is available for sale in the USA through our authorized dealers and direct distribution network. We provide full sales support, installation, and after-sales service nationwide.

The LOG S8 90 Ton model features a servo hydraulic system, intelligent control panel, fast injection speed, and energy-saving operation. It ensures stable production, consistent part quality, and low maintenance costs—making it an excellent choice for precision molding.

You can easily request a quote by contacting LOG’s sales department through our website or authorized representatives. Our team will provide pricing details, technical specifications, and available delivery options based on your production requirements.