Coming Soon! The Go-To Portal for Injection Molding Machines & Spare Parts Keep Me Updated

The LOG-S9 140 ton is an affordable, high-precision, high-speed plastic injection molding machine that focuses on operational efficiency and productivity.

Its modular design, extensive tie-bar space, unique rigid third-platen flange, and highly adjustable ejector and L/D ratio enable a wider range of mold sizes, allowing for quick and easy mold changes. The new dual-cylinder injector provides increased pressure, resulting in improved surface finish and dimensional accuracy.

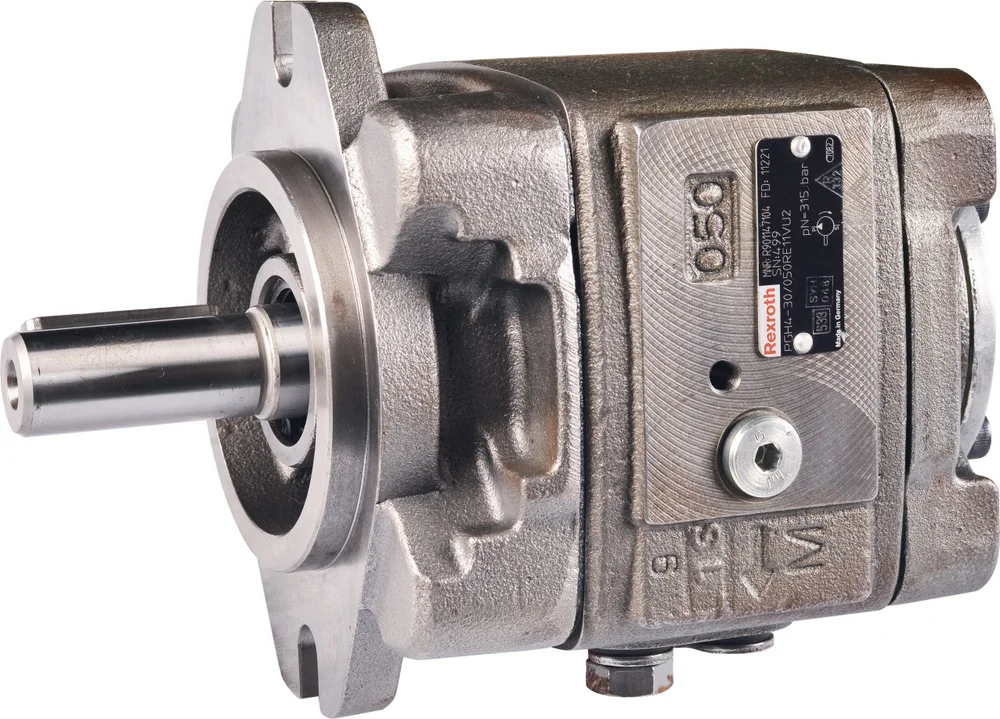

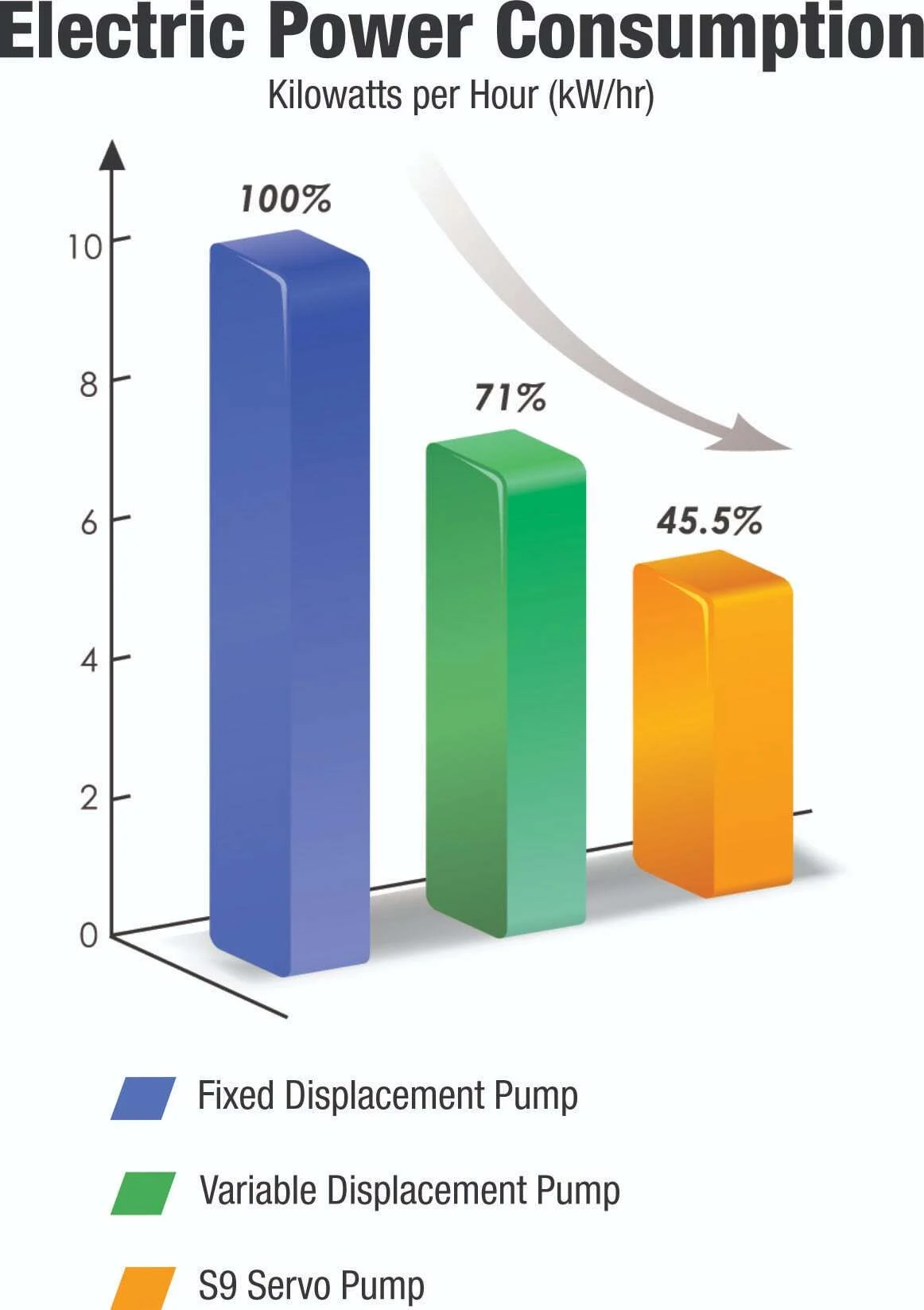

The 5-point dual-toggle mechanism has been redesigned to improve durability while applying high clamping forces directly, thereby reducing cavity deformation. The enlarged high-power servo-hydraulic system efficiently produces a clamping force of 140 metric tons. Its increased flow improves operating speed and cuts energy consumption by up to 80%.

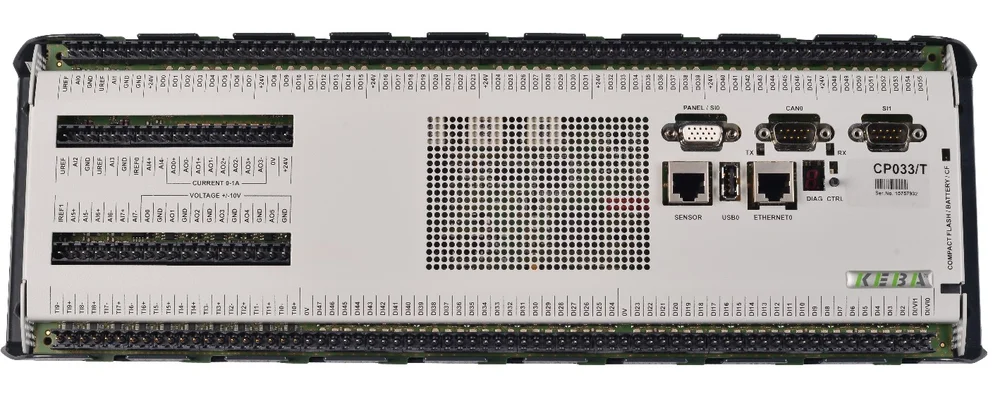

The user-friendly control system handles all operational functions and utilizes well-known international components, facilitating easier maintenance and reducing downtime.

The LOG-S9 140 ton is ideally suited for producing high-quality products across various industries, including food packaging, household products and appliances, electronics, automotive parts, pipe fittings, toys, gifts, and other sectors.

| Shot volume(PS) | Screw diameter | Clamping force | Opening stroke | Tie-Bar Distance | Mold thickness | Pump motor |

|---|---|---|---|---|---|---|

| 239g | 42mm | 1400kn | 380mm | 460 x 410(mm) | 180-500(mm) | 23kw |

Effect Test Cases

Test product: snack box

Material: PP

Weight: 21g

Wall thickness: 0.43mm

2 Cavities

Test condition

Three sets machines

Same oil pump displacement

Same settings

Processing several hours

Processing several hours

Oil temperature hold on 40 degrees

The LOG S9 140 ton Injection Molding Machine is designed for high-speed, precision molding applications. It features an advanced servo-hydraulic system, fast injection response, low energy consumption, and a durable clamping unit to ensure consistent quality and efficiency in production.

The price of the LOG S9 140 ton model varies depending on configuration, optional automation, and customization requirements. For an exact quote, contact LOG’s sales team or an authorized distributor for detailed pricing and specifications.

This machine is widely used in the electronics, medical, packaging, home appliance, and automotive sectors — ideal for producing small to medium-sized plastic parts with tight tolerances and high repeatability.

Yes, it utilizes a high-performance servo system that can reduce energy usage by up to 70% compared to traditional hydraulic systems, offering both cost savings and environmental benefits.

The LOG S9 140 ton Injection Molding Machine is available for sale through LOG’s official sales representatives and authorized dealers in the USA, offering complete installation, training, and after-sales technical support.