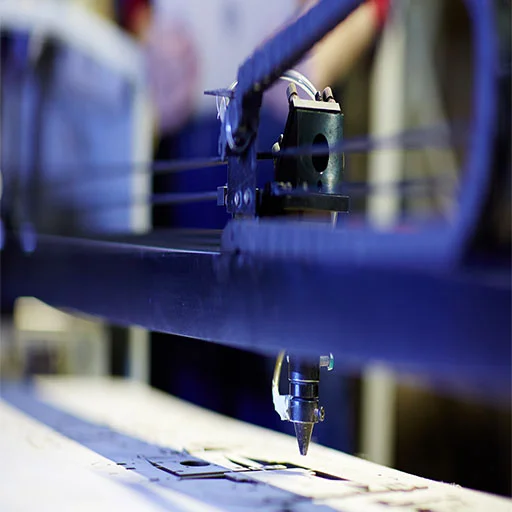

What Is An Injection Molding Machine?

An injection molding machine is the main molding equipment for making thermoplastic or thermosetting plastics into plastic products of various shapes by using plastic molding molds. How an injection molding machine works The working principle of the injection molding machine: utilizing the thrust of the screw (or plunger), the plasticized molten