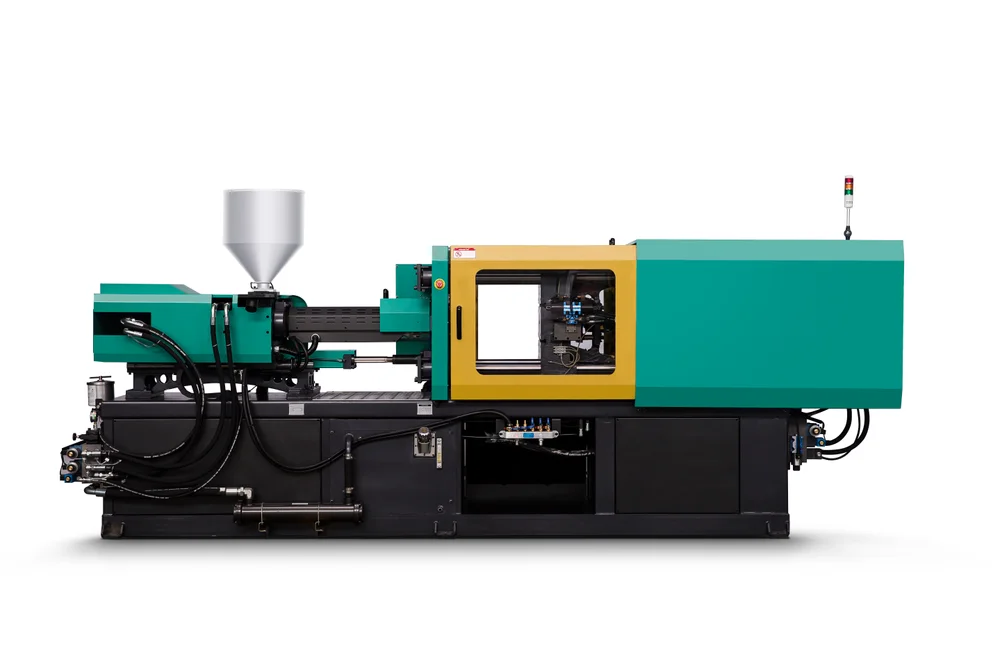

What is Plastic Injection Molding and How Does It Work?

Plastic injection molding is one of the most widely used manufacturing processes in the modern industrial world. From automotive components and medical devices to packaging products and consumer goods, injection molding enables manufacturers to produce high-quality, precision plastic parts at scale. Its ability to deliver consistent dimensional accuracy, fast production